Published on:

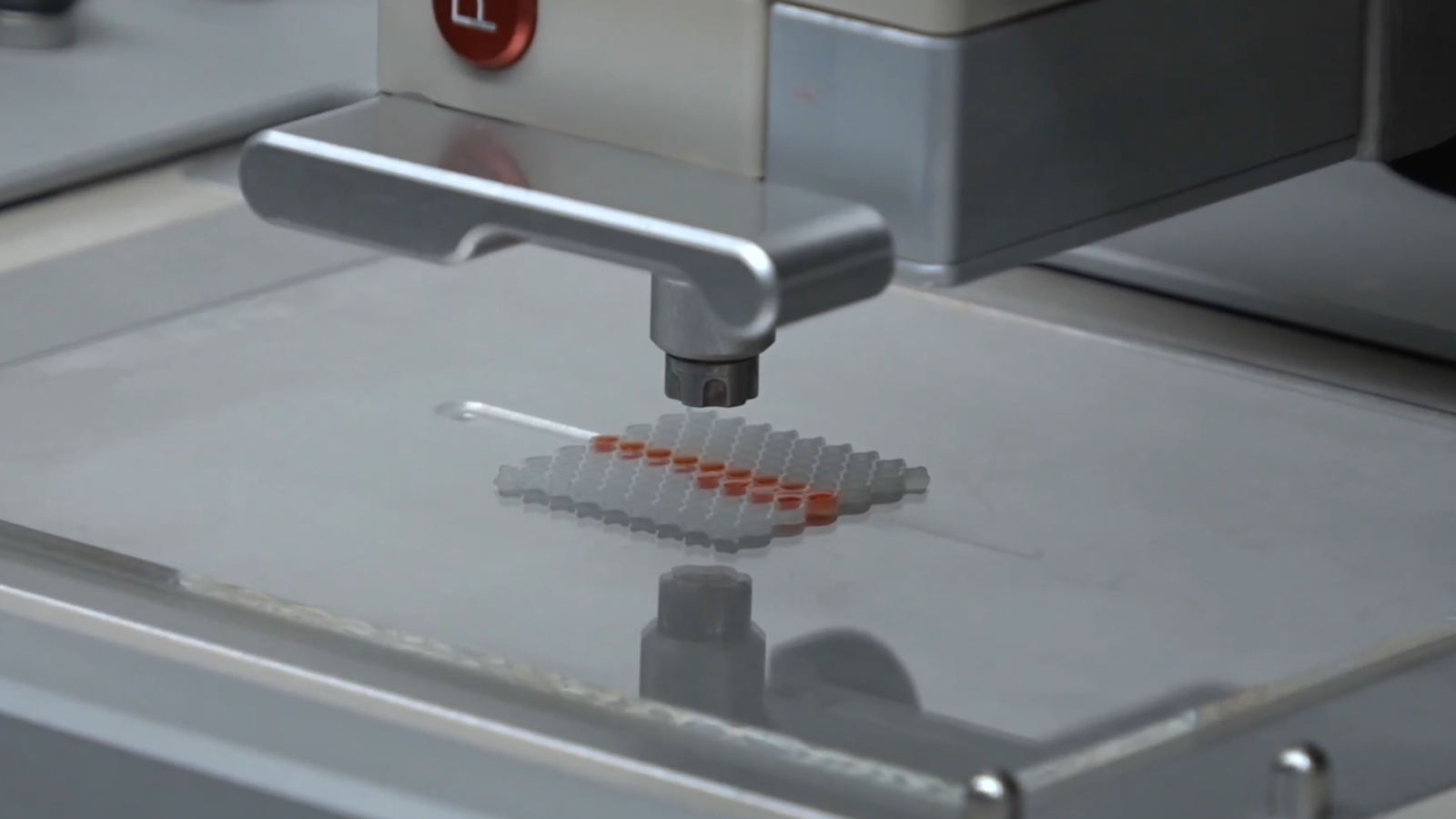

As a pioneer in bioprinting, REGENHU launched its first instrument to the market in 2009. Since then, the company’s primary goal has been to develop cutting-edge technologies for high-precision fluid dispensing, with a particular interest in application fields such as tissue engineering, drug screening, and drug discovery. Our current portfolio (R-GEN series 3D bioprinters) offers a large variety of dispensing and process tools integrated into an automated platform, ensuring printing accuracy with precision down to the micrometric scale. Equipped with Gyger valves, our pneumatic valve-based droplet dispenser allows us to create streams of controlled volume droplets down to 10nL or deposits of continuous fibers.

“At REGENHU, we know fluid dispensing has no limit. That’s why we have created a portfolio of versatile high-precision machines and dedicated software products that give our customers the freedom to push 3D printing beyond expectations”.

To provide the customer with the greatest possible flexibility in terms of fluid processing, REGENHU offers its customers a variety of different valves, each carefully selected according to the customer's needs. Some of the fluids used by customers can be quite aggressive, so our SMLD 300GR valve series was utilized, which offers significant advantages over the standard SMLD 300G series in terms of corrosion and handling of aggressive media.

In addition to direct dispensing from the sapphire nozzle, there is also the option of using adapter nozzles, offering many more application as for example semi-touch applications.

From accurate, nanoscale fluid dispensing to the extrusion of high-viscosity pastes and high-temperature melts, the R-GEN series instruments are an ideal choice for a wide range of applications in bioprinting, pharmaceutics, electronics, and material development. The unique combination of material-optimized printing technologies with the design opportunities provided by our proprietary software (SHAPER) allows the creation of highly organized 3D structures combining multiple material classes.

As an example, 3D bioprinting with the R-GEN platform is a powerful tool for drug discovery and personalized medicine, replacing the need for animal models and donor tissue. It allows the creation of tissue models to imitate the complexity and functionality of healthy and/or diseased tissues. With the combination of multiple cell populations and materials in the same process in an automated and repetitive way, it is possible to create reliable tissue models. These are then used to rapidly screen the effect and efficacy of novel active compounds in drug discovery and to exploit patients’ cells for personalized medicine, enabling customized and on-chip diagnostics and treatments. Due to its versatile and “cell-friendly” dispensing properties, the pneumatic drop dispenser (PDD) equipped with Gyger valves is often used in such cases.

Equipped with electromechanical microvalves, the printhead proposes precise droplet volumes (down to 10nL) and accurate material dispensing for low to mid-viscosity Newtonian and shear-thinning materials (e.g., cell solutions, hydrogels, pharmaceutical compounds, conductive inks). The material extrusion controlled by microvalves allows the usage of lower air pressure compared to standard pressure-based dispensing techniques.