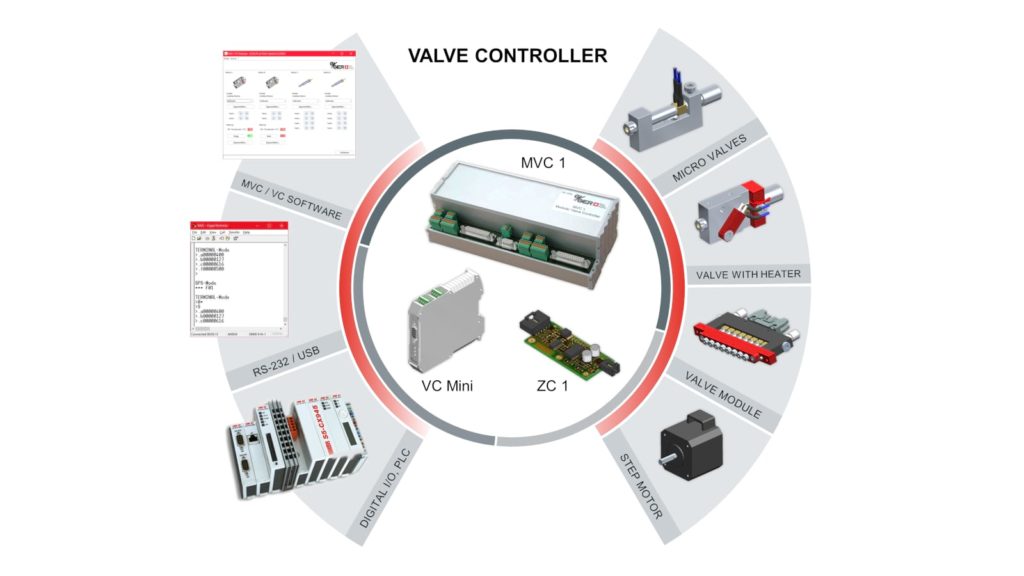

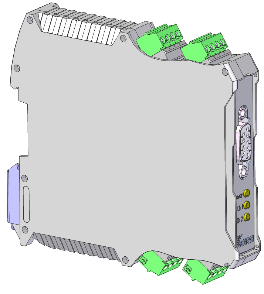

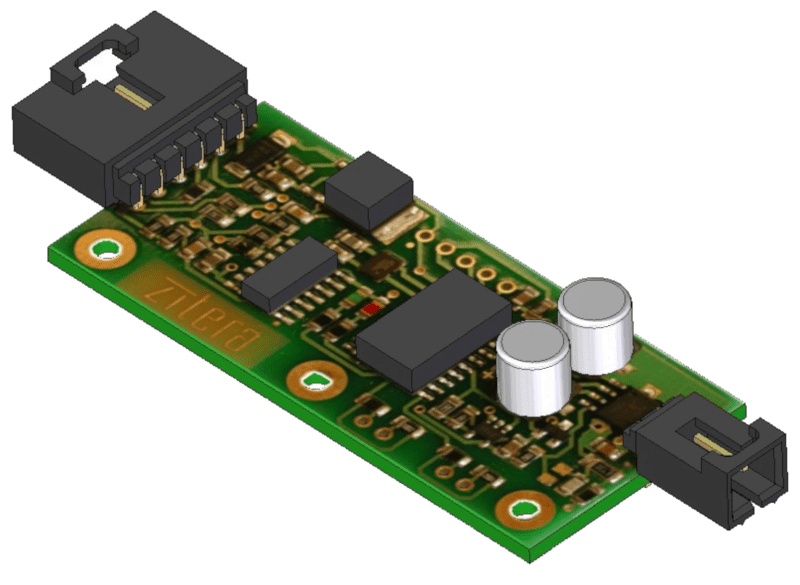

The valve controllers MVC 1, VC Mini and ZC 1 of Gyger provide a complete solution for dispensing applications depending on customer’s needs. The valves and heaters will be configured by a serial interface (R5232 or USB) via Java-Software or direct with commands. This allows the customers, focussed on the requirements of their applications, to integrate the MVC 1 / VC Mini / ZC 1 as an intelligent driver module in existing systems or to use it as a capable stand alone solution.

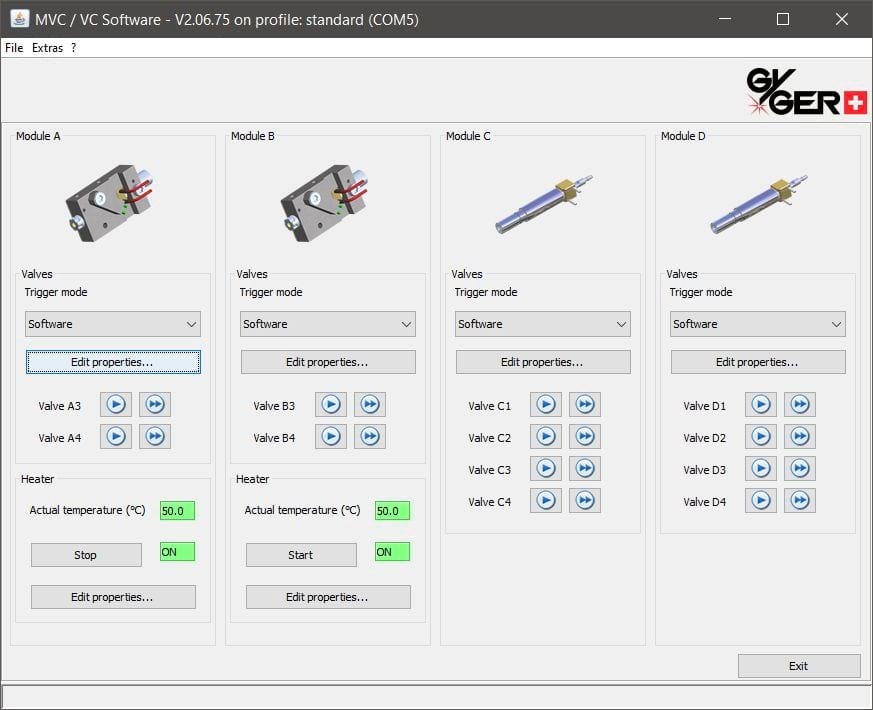

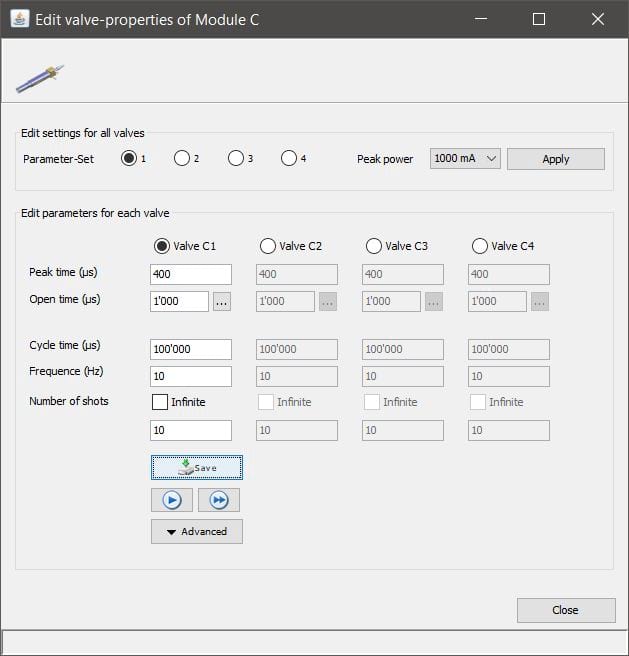

The MVC-Software (Java based) allows a convenient operation via a graphical user interface. All installed power modules and their functions are visualised in the software and the associated parameters (e.g. valve opening time, heating temperature) can be set and precisely matched to the dispensing application. The functions can be controlled directly from the software (e.g. triggering dispensings).

in addition different modes can be set, which allows the operation only over external Hardware-I/O- signals. Complete configuration can be saved on the hard disk and reloaded on demand.

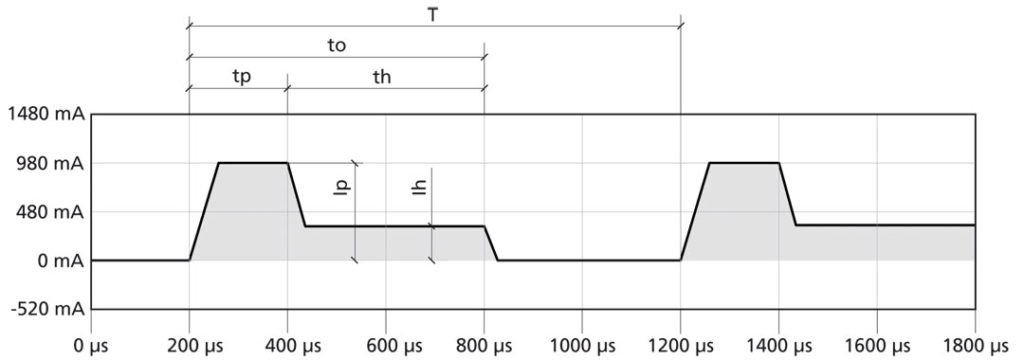

In order to achieve minimum response times with minimum heat development, the electric control should preferably use the “peak and hold” method.

Increasing the peak current for a short time allows the micro valve to be opened quickly under defined conditions. If the micro valve is open, a lower holding current is sufficient during the remaining opening time.

We recommend the Gyger valve controllers for actuation. Precise control of the current curve and optimal cut off when closing the micro valves is thus ensured.

The shielded valve coils are available in versions with soldering pins, completely wired with braids or with connectors.

T Cycle to cycle period

to Valve opening time

tp Peak time

th Holding time

lp Peak current

lh Holding current

More information or a demonstration